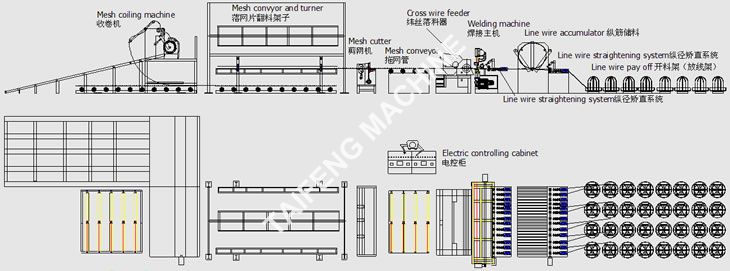

Introduction of automatic wire mesh welding lines:

Both line wire coils and cross wire coils for the auto mesh welding machine are automatically straighten, cut and fed. The finished mesh is also automatically recoiled and cut. Line wires are automatically straightening, storage and feeding. Cross wires are automatically straightening, storage and feeding in the production line. Compared with ordinary reinforcing mesh welding equipment, both line wires and cross wires are fed with coils. Automatically feeding, recoil and cut and discharge the welded mesh roll which maximized save labor and greatly increased production.

| Model | TF-3/6-2500C | |

| Max width of the panel mesh | 2500mm | |

| Max length | 6000 mm | |

| Line wire spacing | 50-200mm | |

| Cross wire spacing | 50-200mm | |

| Wire diameter | 3-6mm | |

| Feeding way | Line wire | In coils |

| Cross wire | In coils | |

| Number of welder | 24points | |

| Max. welding speed | 60-90 meshes/minute | |

| Electric capacity | 500KVA | |

| Air consumption | ≥0.8Mpa, 2m3/min | |

| Cooling water consumption | ≥0.3Mpa, 3m3/min | |

Typical application of welded wire mesh